In view of the energy crisis, the supply security of natural gas moved into the focus of public attention in 2022. As part of this development, the German federal government planned to commission new LNG terminals, and the first one has been online since January 2023. But it is not enough to install new terminals. “The purified natural gas used today is virtually odorless, unlike the town gas used in the past,” explained Lars Hück, the project manager for service at CeH4. “That is why it must be mixed with a clearly perceptible odorant for the safety of end users.” The odorant serves as a warning signal when there is leakage in the public gas supply or private systems. In distribution networks, special odorizing systems are connected to gas pressure regulating and measuring systems.

Short-term order processing thanks to flexible configuration

As part of its network expansion, last year an energy supplier in northern Germany commissioned CeH4 GmbH to odorize the new LNG terminal with the odorant Spotleak 1005. Together with three existing systems, a total of seven new odorizing systems were to be integrated at corresponding grid interconnection points. This resulted in a race against time. In order to ensure supply security throughout the winter months, the systems had to go into operation in December 2022. But Hück was confident: “Based on good experience in the past, we also entrusted LEWA with this time-critical project.”

Odorizing systems for the gases in distribution networks are not off-the-shelf products. In addition to the volume of gas conveyed and the respective pressure range, the odorant used also plays an important role in their design. In order to meet the tight delivery deadlines despite these factors, LEWA relies on freely configurable standard components. As per the contract specifications, in this case CeH4 uses Spotleak 1005, which is composed of 70 percent tetrahydrothiophene (THT) and 30 percent tert-butyl mercaptan (TBM). “It is important to meter the odor-intensive odorant very precisely,” explained Ingo Janßen, the area sales manager at LEWA. “The new terminal feeds an average of 200,000 m3/h, so to suit the intended network interconnection points we supplied six OD60s, each with a 60-liter explosion-proof tank, and one OD450 with a 450-liter tank – all with optical level control.”

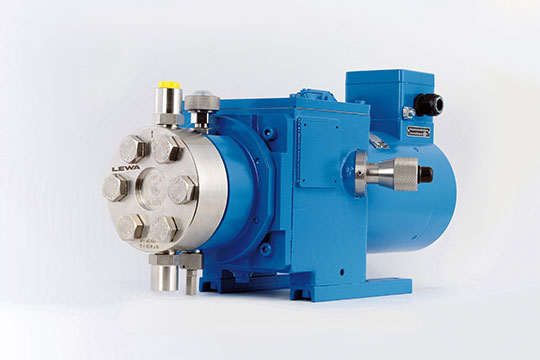

High-precision diaphragm micro-metering pumps in a weatherproof setup

Each of the seven models is equipped with hydraulically actuated, solenoid-driven micro-metering pumps characterized by a high metering accuracy of +/- 1 percent at the lowest flow rates. Their diffusion-tight and durable metal diaphragm prevents leakage and system failures. “The smaller OD60 models operate at a maximum working pressure of 20 bar with a flow rate of 0.17 l/h, so the smallest pump variant – MAH – is used here,” Janßen said. “The OD450, on the other hand, has an MLM pump that can deliver 0.5 l/h at a maximum pressure of 560 bar.” Thanks to the virtually pressure-independent pumping characteristic, constant monitoring of the pump capacity with the KMM 1 flow meter is simple and precise.

Due to their outdoor installation, it was necessary to reliably protect the odorizing systems against all weather conditions. Therefore, the manufacturer installed them in matching stainless steel cabinets tailored to the respective container sizes of 60 and 450 liters. However, the experienced fitters had to come up with a creative solution for the placement of the control system. “We were confronted with the challenge of accommodating the control system outside the Ex-zone but at the same time protected from the weather,” said Michael Töpel, who as the ESMR project manager at CeH4 was responsible for the electrical part of the odorizing systems. “To meet both conditions, we finally decided to mount them externally on appropriate supports.”

LEWA wins the race against time

Due to the 2022 energy crisis, it was imperative to deliver the new odorizing systems in just five months: by November. With its on-time commissioning on December 15 and the adaptation of an existing system – also by the pump manufacturer –, the energy supplier was able to bring the LNG terminal online as early as January 2023, thus ensuring the supply of natural gas over the winter months. The new odorizing systems are expected to remain in use there until mid-2024. “All in all, we needed a complete technical solution in a mobile system for our customer. With the odorizing systems, including the suitable containers in weather-resistant stainless steel cabinets, LEWA met the requirements to our satisfaction despite the tight project time frame,” Hück said in summary.