Description

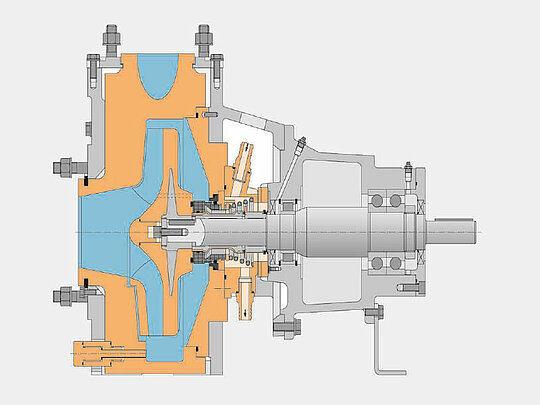

Munsch Standardized NPC and NPC-B chemical pump

Chemical handling pump

The NPC series chemical pumps are the solution of choice for pumping fluids posing an environmental or health hazard such as acids and alkalis or solvents as well as chemically contaminated fluids in the presence or in the absence of solids. Typical applications include the chemical and pharmaceutical industries, electrolysis plants, electroplating plants, the metallurgical and metal finishing industries.

Process pump design with dimensions to EN 22858/ISO 2858. Complemented by Size 40-25-125 and 40-25-160

Advantages

Good reasons for a Munsch Pump Series NPC and NPC-B.

Continuous flushing, efficient and economical

Continuous flushing effectively protects the seal faces from contact with solids. It ensures reliable protection of the mechanical seal when

- there is a risk of dry-running

- the fluid pumped has poor lubricating properties

- the fluid pumped contains undissolved gases

- the fluid is pumped near its boiling point

The throttling passage between the casing cover and the rotating seal ring minimizes flushing medium consumption.

Impeller

- High efficiency, low NPSH requirements

- Mounting unaffected by reverse rotation

Steep Pump Characteristic

Exact operating point.

Double mechanical seal (optional)

Shaft sealing solution for fluids posing an environmental hazard.

Technical Data

| Series | Pump capacity [Q] | Differential head [H] | Operating temperature [t] | Operating pressure [p] | Discharge nozzle | Motor rating |

|---|---|---|---|---|---|---|

| NPC | up to 200 m³/h | up to 90 m | from -20°C to +150 °C | up to 16 bar | DN 25 to DN 65 | up to 30kW |

| NPC-B | up to 150 m³/h | up to 80 m | from -20°C to +150 °C | up to 16 bar | DN 25 to DN 65 | up to 18,5kW |

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

Amine treatment

At LEWA, you receive pumps and systems for amine treatment in power plants. Ask our experts for more information.

More DetailsPolymerization

LEWA manufactures metering pumps and metering systems for polymerization which optimally meet the necessary requirements. We are happy to help.

More DetailsProduction of biodiesel

LEWA provides metering systems for producing biodiesel and other biofuels. Consult us!

More DetailsDilution of surfactants

Dilution of surfactants such as sodium lauryl ether sulfate (SLES) with LEWA pumps during production of detergents.

More Details